Needing to de-rust a handful of small parts in a hurry, I improvised this rotary tumbler. While this isn't my preferred way to remove rust from large or heavily rusted parts (more on that soon), it's a great way to clean up a bunch of smaller parts while you work on something else.

Grab a coffee can, and let's make a tumbler!

Drill a hole into the base of a metal coffee can, doing your best to place it at the center. Pass a bolt through the hole you just drilled (see image to the right), and tighten it in place using washers (both sides of the hole) and a nylon-threaded lock-nut. If you don't have a lock nut, use a lock washer, or a regular nut and a bit of CA glue to keep it from backing off (and if you're worried, just be sure to spin the drill in the direction that would tend to tighten, rather than loosen, the nut).

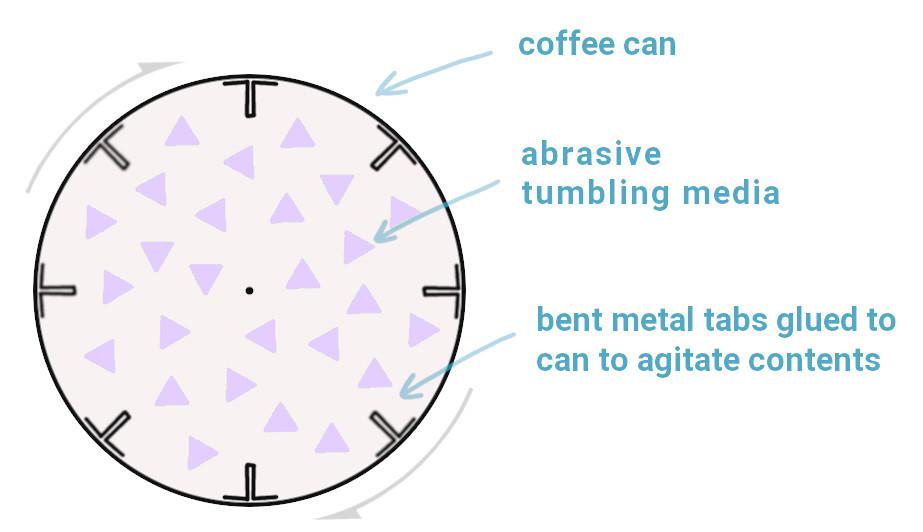

Epoxy fins onto the inside of the can (I used strips of metal cut from another can) to stir items in the can as it spins.

- Place the items you want to polish in the can, along with some abrasive material (ready-made tumbling media, walnut-shells, sand, etc.), and seal it up. Be sure to leave some room in the can, so the contents can move around freely.

- Chuck the bolt into a power drill (a corded drill would be best for this), and find a way to secure both the drill and the can. You'll want the immobilize the drill and constrain the can, such that it can roll freely without bouncing around. I lightly chucked the drill into a vise, using bungee-cords to keep it from slipping out, and rested the can on 360°-casters, using a bit of old v-belt to keep it from jumping up and down.

- Zip-tie (or tape, rubber-band, etc.) the trigger of the drill so that it spins at a comfortable rate. Watch and wait!

To leave a comment below, sign in using Github.